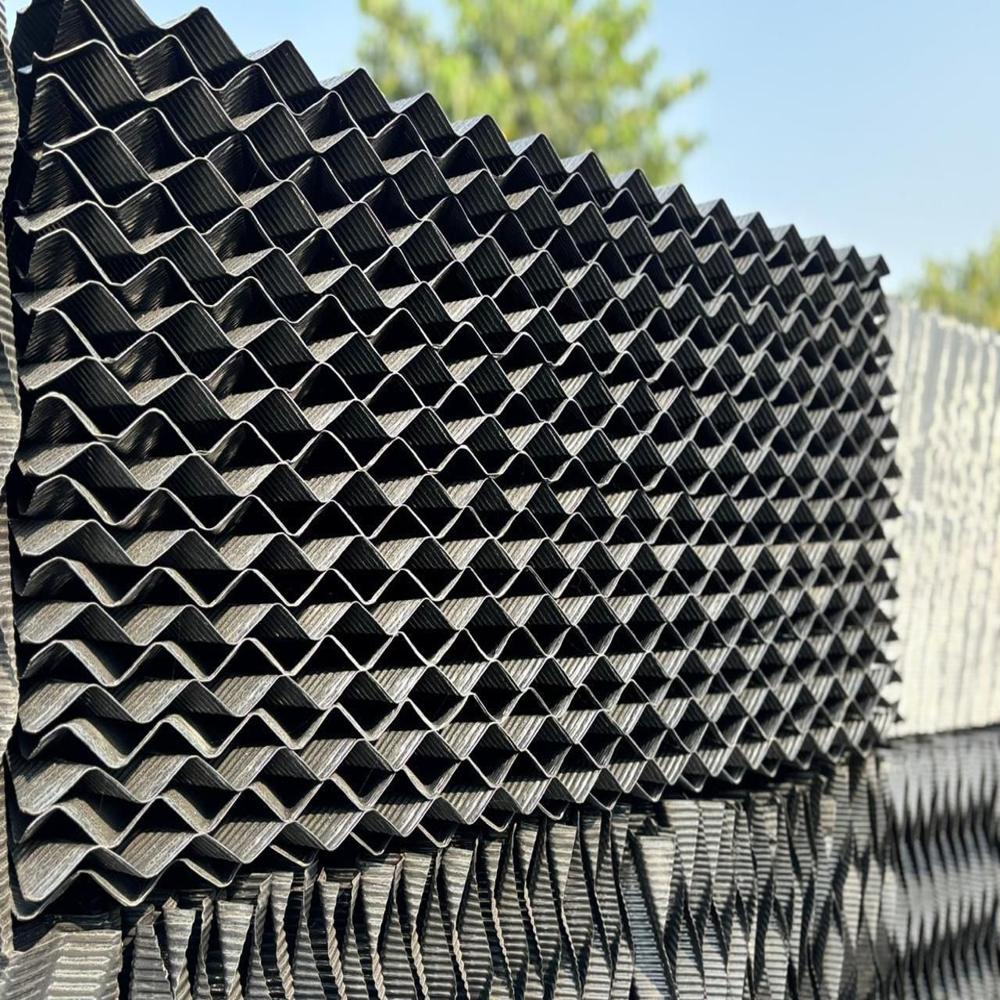

Tube Settler Media

5500.0 INR/Bag

Product Details:

- Shape hexagonal

- Product Type watervfilter part

- Function waste water treatment

- Use STP , ETP & INDUSTRIES

- Material PVC

- Size 500mm, 750mm, or 1000m

- Click to View more

X

Tube Settler Media Price And Quantity

- 1 Bag

- 5500.0 INR/Bag

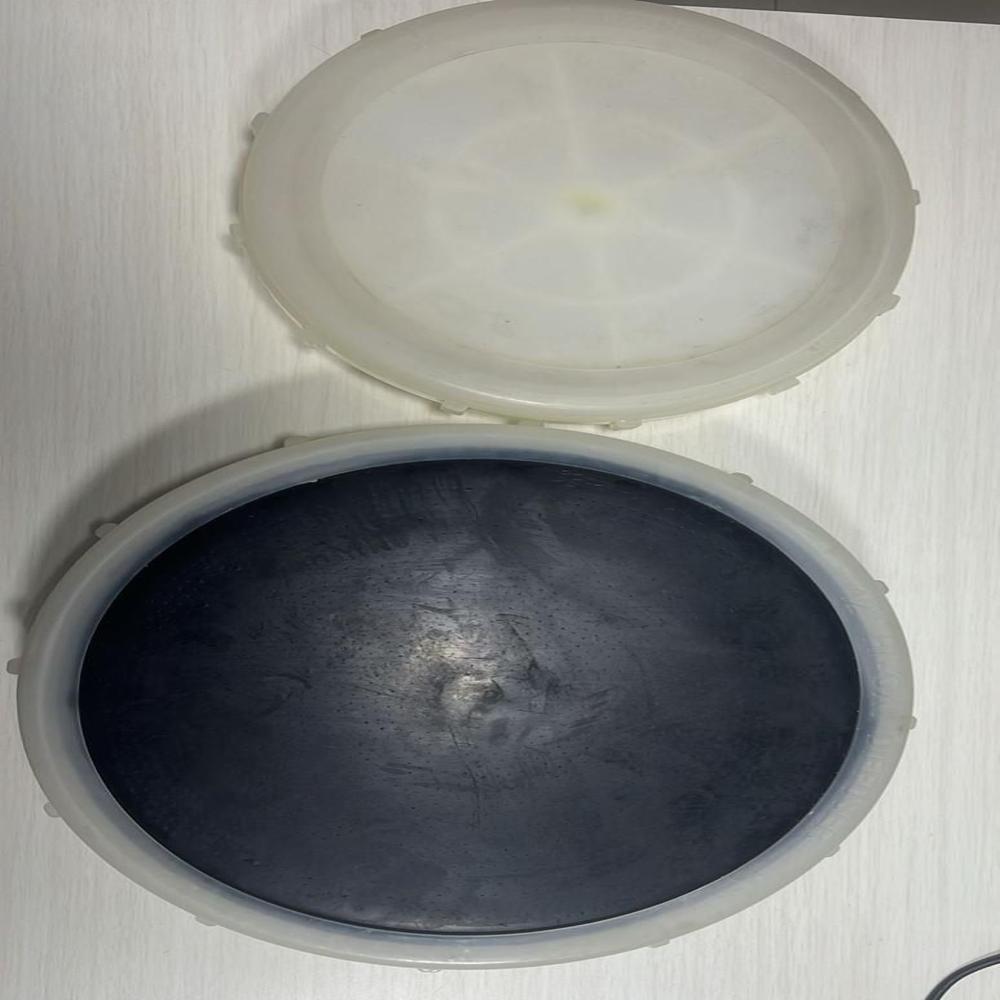

Tube Settler Media Product Specifications

- waste water treatment

- PVC

- STP , ETP & INDUSTRIES

- hexagonal

- watervfilter part

- 500mm, 750mm, or 1000m

Tube Settler Media Trade Information

- 1 Days

Product Description

Tube settler media, also known as lamella clarifier modules, are structured blocks of inclined tubular channels used in water and wastewater treatment to improve sedimentation. They work by reducing the vertical distance a particle must travel to settle, significantly increasing the effective settling area within a clarifier.Key Specifications & Design

- Materials: Primarily manufactured from PVC (Polyvinyl Chloride) for general use or PP (Polypropylene) for high-temperature or aggressive chemical environments.

- Shapes: Typically feature a hexagonal chevron (honeycomb) or square design to maximize structural stability and settling efficiency.

- Inclination Angle: Standard modules are sloped at 60 from the horizontal, which is the optimal angle to allow settled sludge to slide down naturally for collection.

- Common Dimensions:

- Module Height: 500mm, 750mm, or 1000mm.

- Sheet Thickness: Standard thickness is usually 1.0mm to 1.5mm.

- Cross-Sectional Area: Often standardized around 120mm x 44mm for hexagonal types.

Core Benefits

- Increased Capacity: Can allow clarifiers to operate at 2 to 4 times the normal flow rate of conventional basins.

- Space Optimization: Reduces the required footprint for new installations by up to 50%.

- Cost Efficiency: Provides an inexpensive way to upgrade existing plants (retrofitting) to improve performance without heavy civil construction.

- Reduced Chemicals: Often allows for a reduction in coagulant dosage while maintaining water clarity.

Applications

- Municipal Plants: Drinking water purification and Sewage Treatment Plants (STP).

- Industrial Use: Effluent Treatment Plants (ETP) for chemical, pharmaceutical, dairy, and food processing industries.

- Specialized Systems: Used in primary/secondary clarifiers and as oil-water separators.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email